Page 17 - HIWT Summer 2016 World of Welding

P. 17

Required topics that were taught for badge programs:

One hour classroom related instructions on the following:

Safety in a metal shop

Careers in welding and metal fabrication trades

Oxy/act fuel safety and cutting

Hand held Plasma cutting

GMAW weld process

SMAW weld process

Types of electrode and filler wire

PPE safety equipment

Basic metallurgy – type of metals – alloys – periodic table of

elements –

How carbon affects iron

Alum, Stainless, carbon steel, bronze, copper , steel, wrought iron

Tool making – Annealing, quenching, tempering, hardening.

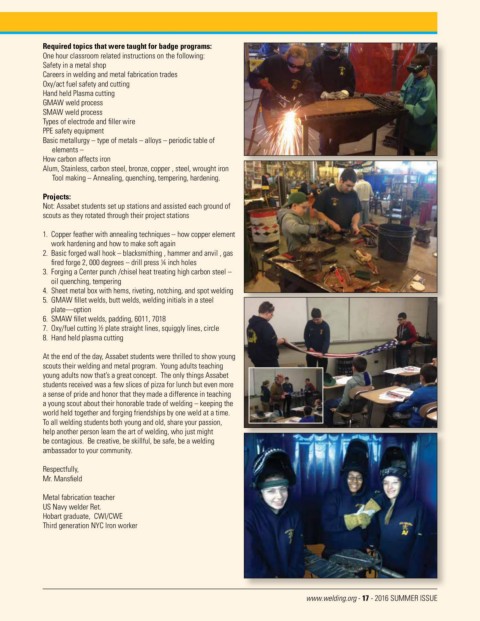

Projects:

Not: Assabet students set up stations and assisted each ground of

scouts as they rotated through their project stations

1. Copper feather with annealing techniques – how copper element

work hardening and how to make soft again

2. Basic forged wall hook – blacksmithing , hammer and anvil , gas

fired forge 2, 000 degrees – drill press ¼ inch holes

3. Forging a Center punch /chisel heat treating high carbon steel –

oil quenching, tempering

4. Sheet metal box with hems, riveting, notching, and spot welding

5. GMAW fillet welds, butt welds, welding initials in a steel

plate—option

6. SMAW fillet welds, padding, 6011, 7018

7. Oxy/fuel cutting ½ plate straight lines, squiggly lines, circle

8. Hand held plasma cutting

At the end of the day, Assabet students were thrilled to show young

scouts their welding and metal program. Young adults teaching

young adults now that’s a great concept. The only things Assabet

students received was a few slices of pizza for lunch but even more

a sense of pride and honor that they made a difference in teaching

a young scout about their honorable trade of welding – keeping the

world held together and forging friendships by one weld at a time.

To all welding students both young and old, share your passion,

help another person learn the art of welding, who just might

be contagious. Be creative, be skillful, be safe, be a welding

ambassador to your community.

Respectfully,

Mr. Mansfield

Metal fabrication teacher

US Navy welder Ret.

Hobart graduate, CWI/CWE

Third generation NYC Iron worker

www.welding.org - 17 - 2016 SUMMER ISSUE