Page 3 - HIWT Fall 2012 World of Welding

P. 3

hiwt@welding.org HOBART INSTITUTE OF WELDING TECHNOLOGY

FINANCIALLY SPEAKING

for the survey in Great Britain. However it may serve as a

reference point for welding cost in these industries and if 2%

By André A. Odermatt of the cost is for weld repairs it represents over 600 million

President dollars!

Hobart Institute of Welding

Technology There are thousands of welders that have not had the

opportunity to be trained at a school such as Hobart Institute

of Welding Technology. It is likely that they have not learned

The Welding Institute, how to identify and read the weld puddle and take corrective

Cambridge, UK has recently actions to create a sound weld. While these welders perform

undertaken a very interesting valuable work for companies, they present an opportunity to

survey amongst 800 reduce manufacturing cost if their skill is enhanced through

professionals dealing with training. Training can bring measurable improvement. The

inspections of welds in several most important factor in measuring the return-on-investment

areas such as pipelines, pipe (ROI) for training is the definition of what the training must

systems, offshore and other achieve. Measuring the amount of money involved in weld

structures, pressure vessels and other manufacturing industries. repair, rework and scrap before and after training, and then

As can typically be expected with surveys, the response rate comparing that improvement with the cost of training, is the

was approximately ten percent. way to measure ROI.

The objective of the survey was to determine the frequency of The TWI report states that “Average repair rates for the Oil &

repair in a welded component expressed in percentage values. Gas and Power sectors range from 1 to 3%. With peak rates

In the majority of the cases, the rates were determined as the up to 25% in specific locations and exceptional values of up to

fraction of the length of repaired weld versus the total weld 55%.” Major factors affecting repair rates are welder skills,

length. In other cases the respondents referred to the number location or accessibility of welds and poor fit-up prior welding.

of repaired welds versus the total number of welds.

Financially speaking, welder training seems to pay-off

From an industry standpoint, the highest repair rates (3%) handsomely!

were found in piping systems and onshore

pipelines. From a materials view point the

highest repair rates were found in low alloy

and Ni-alloy steels (3.1% and 3.4%).

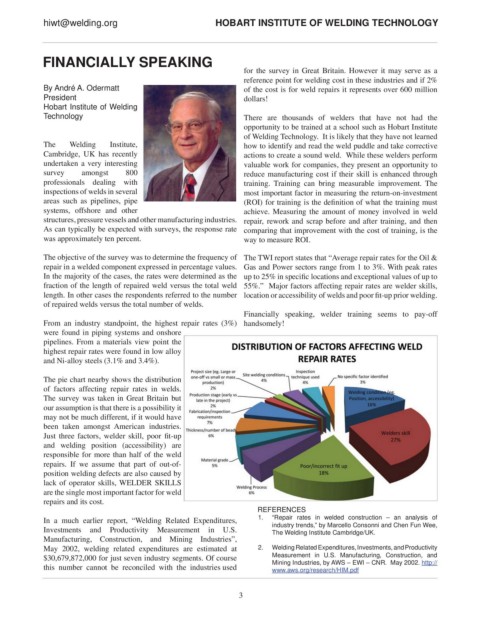

The pie chart nearby shows the distribution

of factors affecting repair rates in welds.

The survey was taken in Great Britain but

our assumption is that there is a possibility it

may not be much different, if it would have

been taken amongst American industries.

Just three factors, welder skill, poor fi t-up

and welding position (accessibility) are

responsible for more than half of the weld

repairs. If we assume that part of out-of-

position welding defects are also caused by

lack of operator skills, WELDER SKILLS

are the single most important factor for weld

repairs and its cost.

REFERENCES

In a much earlier report, “Welding Related Expenditures, 1. “Repair rates in welded construction – an analysis of

Investments and Productivity Measurement in U.S. industry trends,” by Marcello Consonni and Chen Fun Wee,

The Welding Institute Cambridge/UK.

Manufacturing, Construction, and Mining Industries”,

May 2002, welding related expenditures are estimated at 2. Welding Related Expenditures, Investments, and Productivity

$30,679,872,000 for just seven industry segments. Of course Measurement in U.S. Manufacturing, Construction, and

this number cannot be reconciled with the industries used Mining Industries, by AWS – EWI – CNR. May 2002. http://

www.aws.org/research/HIM.pdf

3