Page 20 - HIWT Summer 2013 World of Welding

P. 20

THE WORLD OF WELDING http://www.welding.org

PIPELINING GETS IN YOUR BLOOD

This group of pipeliners welds on gas

mains, some new installation, as well

as maintenance and replacement of

older lines.

John Dietiker had formal welding

training after high school and worked

in fabrication shops for about ten

years before getting into pipelining.

“I made the change for better money,”

John commented.

John had taken the Pipe Layout for

Fitters and Welders course last year

at Hobart Institute before returning

in 2013 for the blueprint course.

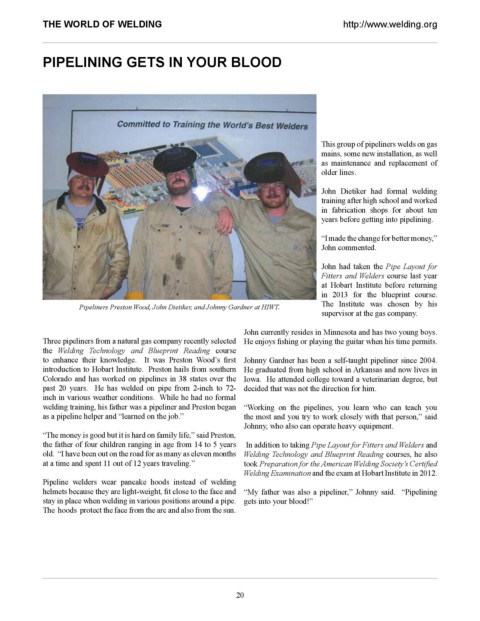

Pipeliners Preston Wood, John Dietiker, and Johnny Gardner at HIWT. The Institute was chosen by his

supervisor at the gas company.

John currently resides in Minnesota and has two young boys.

Three pipeliners from a natural gas company recently selected He enjoys fishing or playing the guitar when his time permits.

the Welding Technology and Blueprint Reading course

to enhance their knowledge. It was Preston Wood’s first Johnny Gardner has been a self-taught pipeliner since 2004.

introduction to Hobart Institute. Preston hails from southern He graduated from high school in Arkansas and now lives in

Colorado and has worked on pipelines in 38 states over the Iowa. He attended college toward a veterinarian degree, but

past 20 years. He has welded on pipe from 2-inch to 72- decided that was not the direction for him.

inch in various weather conditions. While he had no formal

welding training, his father was a pipeliner and Preston began “Working on the pipelines, you learn who can teach you

as a pipeline helper and “learned on the job.” the most and you try to work closely with that person,” said

Johnny, who also can operate heavy equipment.

“The money is good but it is hard on family life,” said Preston,

the father of four children ranging in age from 14 to 5 years In addition to taking Pipe Layout for Fitters and Welders and

old. “I have been out on the road for as many as eleven months Welding Technology and Blueprint Reading courses, he also

at a time and spent 11 out of 12 years traveling.” took Preparation for the American Welding Society’s Certified

Welding Examination and the exam at Hobart Institute in 2012.

Pipeline welders wear pancake hoods instead of welding

helmets because they are light-weight, fit close to the face and “My father was also a pipeliner,” Johnny said. “Pipelining

stay in place when welding in various positions around a pipe. gets into your blood!”

The hoods protect the face from the arc and also from the sun.

20