Page 3 - WOW Summer 2023

P. 3

Summer 2023

Being a welder is MUCH more than just working with your hands.

It has been said, “Get a trade if you like working with your hands” which is true. But it’s also true to, “Get a trade

for an incredible career path and prosperity”. Take this quote: “College students excel from the neck up and

tradesman excel from the neck down.”

Today’s welder excels from head to toe. Welding is incredibly technical and requires a high level of intelect. I

talk with hundreds of students each year and these are highly intellectual, critical thinking individuals. Today’s

“welder’s market” requires those individuals to be talanted, competitiive, driven, smart and technically savy

among other things.

Students today coming out of high school career centers are some of the brightest people you will ever meet.

Hobart Institue is full of them and they meet ALL the above welder’s market criteria. Most importantly this is

exactly what employers are looking for. Employers today that are involved in advanced manufacturing are at the

top of the game by investing in some of the most advanced equipment on the market and looking to hire the talent

to produce with these technologies. These are highly intelligent welding individuals that we are producing at our

By Scott A. Mazzulla, President school and should be looked at as the future of manufacturing.

Hobart Institute of Welding Technology

At Hobart Institute a recent survey was conducted and employers told us the top traits they look for. The

survey showed specifically what they want from our students. 1) high level of skill, 2) positive attitude, 3) solid

attendance, and professionalism. Summary, they need to be smart, dependable, driven and talanted. I am proud to say our graduates check all those boxes as

well. They also need the ability and courage to network; for some they need to develop a social game.

There have been several articles written on the benfits of getting a trade. The common themes were, not in any paticular order: Trade School is lower cost

and fast, trades pay well, trades provide job security, high job satisfaction. According to a featured article from Jeremy Anderberg in artofmanliness.com, “an

expected 2.5 million middle-skill jobs (those that require less than a bachelor’s degree but more than a high school diploma) will be added to the workforce,

accounting for an incredible 40% of all job growth.” Certainly, the point is, trades are a highly viable career path and must be taken seriously.

For the high schools that send students to the “career centers”, they are doing students a great service and introducing them to a life long skill that will open

them to an incredible career path. Let’s continue that path from high school to trade school to employment.

Weld Safe and Stay Safe.

Plates and Shapes 3

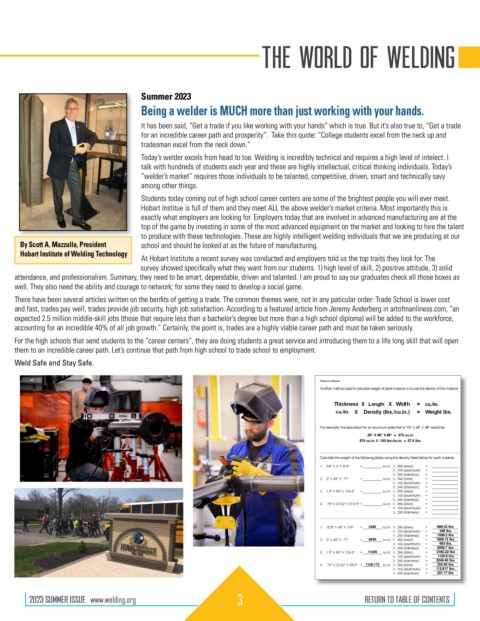

Another method used to calculate weight of plate material is to use the density of the material.

Thickness X Length X Width = cu./in.

cu./in. X Density (lbs./cu.in.) = Weight lbs.

For example, the calculation for an aluminum plate that is 1/4" X 48" X 48" would be:

.25" X 48" X 48" = 576 cu.in.

576 cu.in. X .100 lbs./cu.in. = 57.6 lbs.

Calculate the weight of the following plates using the density listed below for each material.

1. 5/8" X 4' X 9'-8" = __________ cu.in. X .284 (steel) = ______________

X .100 (aluminum) = ______________

X .290 (stainless) = ______________

2. 2" X 45" X 77" = __________ cu.in. X .284 (steel) = ______________

X .100 (aluminum) = ______________

X .290 (stainless) = ______________

3. 1.5" X 60" X 124.5" = __________ cu.in. X .284 (steel) = ______________

X .100 (aluminum) = ______________

X .290 (stainless) = ______________

4. .75" X 22.62" X 5'-6.5" = __________ cu.in. X .284 (steel) = ______________

X .100 (aluminum) = ______________

X .290 (stainless) = ______________

3480

1. .625" X 48" X 116" = __________ cu.in. X .284 (steel) = ______________

988.32 lbs.

X .100 (aluminum) = ______________

348 lbs.

X .290 (stainless) = ______________

1009.2 lbs.

2. 2" X 45" X 77" = __________ cu.in. X .284 (steel) = ______________

6930

1968.12 lbs.

X .100 (aluminum) = ______________

693 lbs.

2009.7 lbs.

X .290 (stainless) = ______________

11205

3. 1.5" X 60" X 124.5" = __________ cu.in. X .284 (steel) = ______________

3182.22 lbs

X .100 (aluminum) = ______________

1120.5 lbs.

X .290 (stainless) = ______________

3249.45 lbs.

1128.173

4. .75" X 22.62" X 66.5" = __________ cu.in. X .284 (steel) = ______________

320.40 lbs.

112.817 lbs.

X .100 (aluminum) = ______________

327.17 lbs.

X .290 (stainless) = ______________

© 2020, Hobart Institute of Welding Technology EW462A / Revised 200515-1

2023 SUMMER ISSUE www.welding.org 3 RETURN TO TABLE OF CONTENTS