Page 4 - HIWT Fall 2011 World of Welding

P. 4

THE WORLD OF WELDING http://www.welding.org

Pass and Maintain d1.1 and d1.5

(Continued from page 3)

tHe tHree-fiVe serViCe PledGe

In addition to certifying current students, the Hobart The full service certification includes the ability to

Institute offers full service welder certifications to establish and qualify welding procedures on all types

industry in a timely manner. Just three days after of ferrous and nonferrous materials and to work with

receipt of the test specimen, a verbal response is procedures set forth by American Welding Society,

given and in just five days, the paperwork is completed ASME, military, or industry-specific specifications.

and available. Full service may also include training of your welders

to prepare them for testing required for certification.

State-of-the-art equipment at Hobart Institute, And it includes HIWT working with you to create an

coupled with the years of experience and expertise improved certification program for your company.

of our staff, allows some companies take advantage

of the vast welding knowledge that resides at HIWT Hobart Institute maintains all hard copy test records

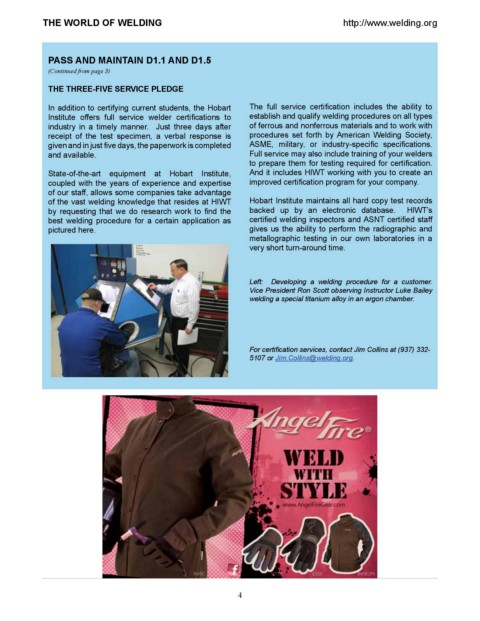

by requesting that we do research work to find the backed up by an electronic database. HIWT’s

best welding procedure for a certain application as certified welding inspectors and ASNT certified staff

pictured here. gives us the ability to perform the radiographic and

metallographic testing in our own laboratories in a

very short turn-around time.

Left: Developing a welding procedure for a customer.

Vice President Ron Scott observing Instructor Luke Bailey

welding a special titanium alloy in an argon chamber.

For certification services, contact Jim Collins at (937) 332-

5107 or Jim.Collins@welding.org.

4