Page 22 - HIWT Summer 2012 World of Welding

P. 22

THE WORLD OF WELDING http://www.welding.org

SETTINGS FOR SMAW UPHILL

By Elmer Swank, Jr.

CWI/CWE - HIWT Instructor

QUESTION:

What polarity does my direct current welding machine need to be on when stick welding a root pass

uphill on mild steel pipe with a 5P+ rod, DCRP or DCSP. I know that welding downhill, the machine should be on DCRP,

but it seems a little hot for uphill.

RESPONSE:

The choice of current type and polarity for shielded metal arc welding depends on the electrode type. The American Welding

Society (AWS) uses a classification system that gives us this information. The AWS classification for the 5P+ electrode is

E-6010.

• The “E” stands for electrode

• The “60” is the minimum tensile strength of the weld in thousand pounds per square inch.

• The “1” indicates that it can be used in all positions

• The last digit identifies the welding current type and polarity. “0” for direct current reverse polarity.

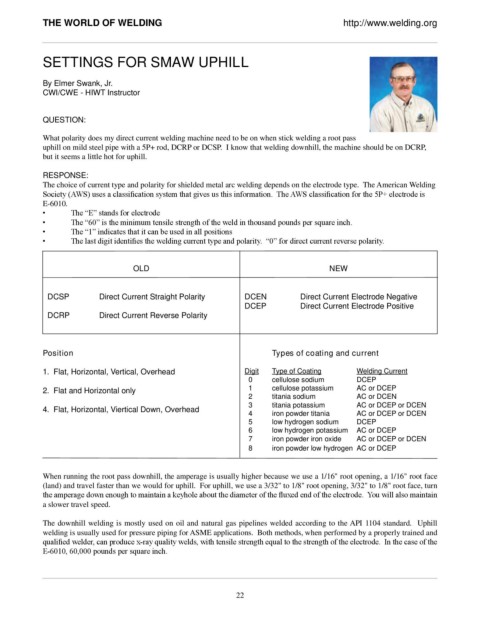

OLD NEW

DCSP Direct Current Straight Polarity DCEN Direct Current Electrode Negative

DCEP Direct Current Electrode Positive

DCRP Direct Current Reverse Polarity

Position Types of coating and current

1. Flat, Horizontal, Vertical, Overhead Digit Type of Coating Welding Current

0 cellulose sodium DCEP

2. Flat and Horizontal only 1 cellulose potassium AC or DCEP

2 titania sodium AC or DCEN

3 titania potassium AC or DCEP or DCEN

4. Flat, Horizontal, Viertical Down, Overhead 4 iron powder titania AC or DCEP or DCEN

5 low hydrogen sodium DCEP

6 low hydrogen potassium AC or DCEP

7 iron powder iron oxide AC or DCEP or DCEN

8 iron powder low hydrogen AC or DCEP

When running the root pass downhill, the amperage is usually higher because we use a 1/16" root opening, a 1/16" root face

(land) and travel faster than we would for uphill. For uphill, we use a 3/32" to 1/8" root opening, 3/32" to 1/8" root face, turn

the amperage down enough to maintain a keyhole about the diameter of the fluxed end of the electrode. You will also maintain

a slower travel speed.

The downhill welding is mostly used on oil and natural gas pipelines welded according to the API 1104 standard. Uphill

welding is usually used for pressure piping for ASME applications. Both methods, when performed by a properly trained and

qualified welder, can produce x-ray quality welds, with tensile strength equal to the strength of the electrode. In the case of the

E-6010, 60,000 pounds per square inch.

22