Page 11 - HIWT Winter 2013 World of Welding

P. 11

hiwt@welding.org HOBART INSTITUTE OF WELDING TECHNOLOGY

COVER STORY

SHARING WELDING EXPERIENCES

By James C. Walters

I completed the nine month

Combination Structural and

Pipe Welding Program in 2002.

Upon completion of the course

at Hobart Institute of Welding

Technology, I moved back to

Middletown, OH where I took

a job with 3D Industries in

Carlisle, OH. At 3D Industries I

worked as a welder, fabricating

as well as repairing various

weldments for the AK Steel

Middletown Works facility.

Eighty percent of our work

was done in the shop but some

duties included field work on

installations of fabricated parts.

The majority of my welding

experience there was FCAW on

.5-in.+ low and medium carbon

steels as well as heavy stainless

applications. The biggest thing

I took from 3D was learning

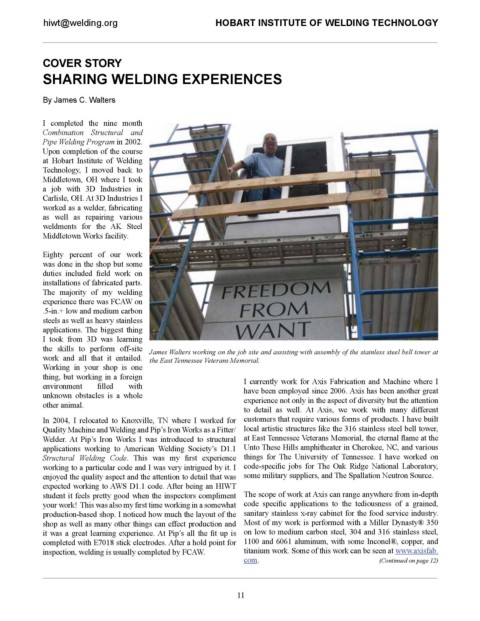

the skills to perform off-site James Walters working on the job site and assisting with assembly of the stainless steel bell tower at

work and all that it entailed. the East Tennessee Veterans Memorial.

Working in your shop is one

thing, but working in a foreign I currently work for Axis Fabrication and Machine where I

environment filled with have been employed since 2006. Axis has been another great

unknown obstacles is a whole experience not only in the aspect of diversity but the attention

other animal.

to detail as well. At Axis, we work with many different

In 2004, I relocated to Knoxville, TN where I worked for customers that require various forms of products. I have built

Quality Machine and Welding and Pip’s Iron Works as a Fitter/ local artistic structures like the 316 stainless steel bell tower,

Welder. At Pip’s Iron Works I was introduced to structural at East Tennessee Veterans Memorial, the eternal flame at the

applications working to American Welding Society’s D1.1 Unto These Hills amphitheater in Cherokee, NC, and various

Structural Welding Code. This was my first experience things for The University of Tennessee. I have worked on

working to a particular code and I was very intrigued by it. I code-specific jobs for The Oak Ridge National Laboratory,

enjoyed the quality aspect and the attention to detail that was some military suppliers, and The Spallation Neutron Source.

expected working to AWS D1.1 code. After being an HIWT

student it feels pretty good when the inspectors compliment The scope of work at Axis can range anywhere from in-depth

your work! This was also my first time working in a somewhat code specific applications to the tediousness of a grained,

production-based shop. I noticed how much the layout of the sanitary stainless x-ray cabinet for the food service industry.

shop as well as many other things can effect production and Most of my work is performed with a Miller Dynasty® 350

it was a great learning experience. At Pip’s all the fit up is on low to medium carbon steel, 304 and 316 stainless steel,

completed with E7018 stick electrodes. After a hold point for 1100 and 6061 aluminum, with some Inconel®, copper, and

inspection, welding is usually completed by FCAW. titanium work. Some of this work can be seen at www.axisfab.

com. (Continued on page 12)

11