Page 22 - HIWT Winter 2013 World of Welding

P. 22

THE WORLD OF WELDING http://www.welding.org

WELDING STUDENTS LEARN THE ART OF BUILDING AND

WELDING STEEL RAILING

By Neil Mansfield

AWS CWI-CWE®

Most welding vocational instructors from around the

country have, at one time or another, built a set of hand

railings or steel stairs. Near Boston, Massachusetts,

Mr. George Aziz, who is a metal fabrication / welding

teacher at Assabet Valley Regional Technical High

School located in central Massachusetts, has a unique

project that he has developed and fine-tuned with his

junior classes throughout the years.

Teaching the next generation of welders and fabricators

to design, fabricate and weld is the core of any

vocational welding program and by including layout,

fabricating and welding is an excellent way to introduce

young welders to the art of building stairs and railings,

which is a key skill to develop. The students get the

fundamentals while being able to use their creative

talents.

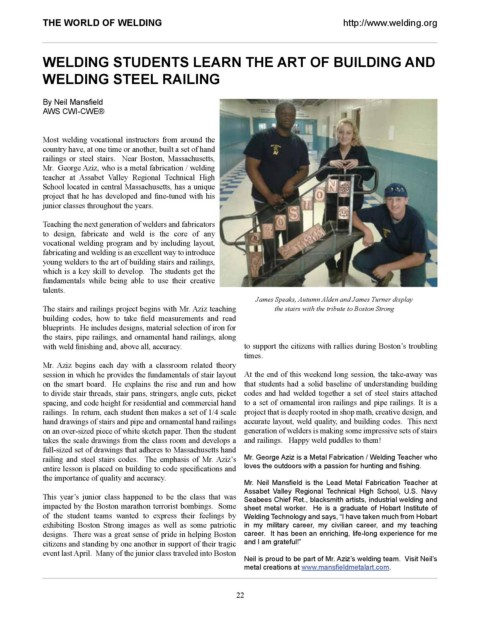

James Speaks, Autumn Alden and James Turner display

The stairs and railings project begins with Mr. Aziz teaching the stairs with the tribute to Boston Strong

building codes, how to take field measurements and read

blueprints. He includes designs, material selection of iron for

the stairs, pipe railings, and ornamental hand railings, along

with weld finishing and, above all, accuracy. to support the citizens with rallies during Boston’s troubling

times.

Mr. Aziz begins each day with a classroom related theory

session in which he provides the fundamentals of stair layout At the end of this weekend long session, the take-away was

on the smart board. He explains the rise and run and how that students had a solid baseline of understanding building

to divide stair threads, stair pans, stringers, angle cuts, picket codes and had welded together a set of steel stairs attached

spacing, and code height for residential and commercial hand to a set of ornamental iron railings and pipe railings. It is a

railings. In return, each student then makes a set of 1/4 scale project that is deeply rooted in shop math, creative design, and

hand drawings of stairs and pipe and ornamental hand railings accurate layout, weld quality, and building codes. This next

on an over-sized piece of white sketch paper. Then the student generation of welders is making some impressive sets of stairs

takes the scale drawings from the class room and develops a and railings. Happy weld puddles to them!

full-sized set of drawings that adheres to Massachusetts hand

railing and steel stairs codes. The emphasis of Mr. Aziz’s Mr. George Aziz is a Metal Fabrication / Welding Teacher who

entire lesson is placed on building to code specifications and loves the outdoors with a passion for hunting and fishing.

the importance of quality and accuracy.

Mr. Neil Mansfield is the Lead Metal Fabrication Teacher at

Assabet Valley Regional Technical High School, U.S. Navy

This year’s junior class happened to be the class that was Seabees Chief Ret., blacksmith artists, industrial welding and

impacted by the Boston marathon terrorist bombings. Some sheet metal worker. He is a graduate of Hobart Institute of

of the student teams wanted to express their feelings by Welding Technology and says, “I have taken much from Hobart

exhibiting Boston Strong images as well as some patriotic in my military career, my civilian career, and my teaching

designs. There was a great sense of pride in helping Boston career. It has been an enriching, life-long experience for me

citizens and standing by one another in support of their tragic and I am grateful!”

event last April. Many of the junior class traveled into Boston

Neil is proud to be part of Mr. Aziz’s welding team. Visit Neil’s

metal creations at www.mansfieldmetalart.com.

22