Page 16 - HIWT Fall 2017 World of Welding

P. 16

A Fabricated Fish Story to children and adults. Four 8” round plates with mounting holes

were plasma cut and welded to the ends of the arches. These would

By Paul Goldman and Neil Mansfield serve as the base to bolt the sculpture into concrete. As described

This is the story of a fish sculpture fabricated with river trash to by Nick Hackett, “Much time was spent working with Andy (Moore)

sound out an environmental message. It is also the story of a river tweaking the head and mounts with a pipe rolling machine, and

organization, OARS, a public school, Assabet Valley Regional hand plasma cutting them to fit near perfect. The base plates were

Technical High School (AVRTHS), and a town, Hudson, MA, that drawn in AutoCAD and burned out with a CNC plasma, for a tight

collaborated to make it a reality. fit when the entire sculpture is to be bolted into the ground.” The

chimes and strikers were welded into its own sub-frame which was

In 2016, OARS (www.oars3rivers.org) celebrated its 30th year then welded into the fish support structure. Overall size is 6.5’ long

of protecting the Assabet, Sudbury and Concord Rivers of and 4.5’ high.

Massachusetts. To commemorate this event, Board Member Dr.

Paul Goldman suggested a sculpture with an environmental theme Several unique features of this sculpture include the welding of

made from metal debris pulled out of the river during their upcoming the chimes and their associated strikers, and the fish eye. Most

Annual River Cleanup. The Board agreed and among the tons of xylophone chimes are mounted with supports running through

trash hauled out, two bicycle frames were found that would become the tube, but our design only places one weld at each end, at

integral parts of the sculpture. the hanging points, of each tube. This produced a nice tone, and

contributed to the aesthetics by visually showing the front of the

The design was a metal fish with the river trash incorporated as chimes without supports. For safety, it was decided to use strikers

musical chimes, making it an interactive xylophone. Obviously with limited range. A simple pivot design using flat bearings, metal

welding was required, so Goldman contacted Neil Mansfield, Metal rods, washers and nuts produced a nice sound and minimized

Fabrication Lead Teacher at AVRTHS in Marlborough, MA. The concealed areas to discourage corrosion. This simple design also

learning opportunity for the students in terms of welding a complex made it easy to weld the six strikers needed to ensure that all users

interactive pubic sculpture incorporating safety (complying with have access. Matt Leger’s musical talents proved especially helpful.

playground regulations), ease of use for children and handicap, Leger describes his role, “I had to redesign all of the chimes to

musical capability, and promoting civic pride quickly convinced resonate well and be tuned correctly.” He also created key features

Mansfield this was a worthy project. in the strikers. In addition to the chimes, the fish eye is also made

The tubes from the two bicycle frames formed the core of the from river trash, i.e., a chainring sprocket. Since the chainring

sculpture. First, it had to be determined what size chimes could teeth are relatively sharp, rather than grinding them down, Hackett

be cut from the frames and what their musical notes would be. suggested blacksmithing an eye socket and fit it inside. Welding

Goldman did the research using the website http://leehite.org/ it in place produced an attractive and safe design. These features

Chimes.htm to calculate lengths and notes based on the tubes were created in large part by the students using their knowledge

OD, ID and material, i.e. steel. The pentatonic scale was chosen and insights of welding and blacksmithing.

for its pleasant sound, and the notes A, C, D, E, G, and A selected After carefully deburring and inspecting the sculpture’s

based on available tube lengths. Knowing there would be 6 chimes approximately 150 welds, it was time for painting. Ken Stukonis,

ranging in length from 20.5” to 12.5”, and each spaced 3” apart Automotive Collision Lead Teacher, guided his students on selecting

allowed for the supporting fish-shaped structure to be designed. paints that would survive New England weather. The color scheme

Sara Cone explains, “We (Cone and Kallee Clark) had to design and is silver for all the metal not from the river; the six chimes are the

completely come up with a sculpture from scratch. Goldman had colors of the rainbow, i.e., purple, blue, green, yellow, orange and

the bike parts and he knew he wanted to build a sculpture using the red; and the fish eye is green. The inside of the tubes are painted

river bikes that reflected back to the river and give awareness. We with black automotive undercoat. And, finally, the entire sculpture is

had created the fish, a full scale blueprint by hand drawing on top of given several clear protective layers.

tables. Later we bent the pipe and tacked the fish shape together.”

While the fabrication portion of the story is fascinating, the fact

The support structure was made from stock 1.25” diameter steel is without a place to display it, the story is incomplete. The two

tubing. Using the full scale sketch as a template, the tacked bicycles were pulled out of the Assabet River in Hudson, MA so it

structure was confirmed and then welded. Once the fish outline was the perfect home for the sculpture; particularly since the

was completed, two arches were made to raise the sculpture to a Assabet River Rail Trail runs through

height accessible the town and along the river.

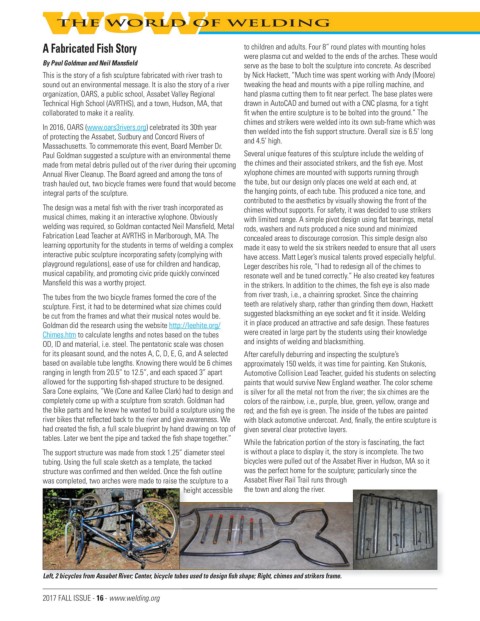

Left, 2 bicycles from Assabet River; Center, bicycle tubes used to design fish shape; Right, chimes and strikers frame.

2017 FALL ISSUE - 16 - www.welding.org www.welding.org - 17 - 2017 FALL ISSUE