Page 4 - HIWT Winter 2011 World of Welding

P. 4

THE WORLD OF WELDING http://www.welding.org

neW! Online cOuRSe!

ReacHinG OuT TO yOu WiTH ViSual inSPecTiOn

This course concentrates on the single most used method of welding inspection — what we can see with the naked eye. Anyone involved

with arc welding inspection, quality control, engineering or supervision should know the fundamentals of what to observe,

prior to, during and after welding.

During this course you will learn about:

• Description and functions of common weld gages

• Temperature indicators

• Marking repair welds

• Visual Inspection prior to welding

• Visual Inspection during welding

• Visual Inspection after welding

• Equipment required

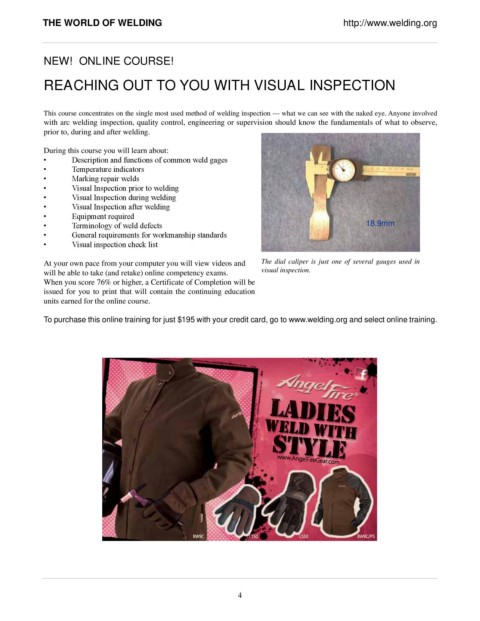

• Terminology of weld defects 18.9mm

• General requirements for workmanship standards

• Visual inspection check list

At your own pace from your computer you will view videos and The dial caliper is just one of several gauges used in

will be able to take (and retake) online competency exams. visual inspection.

When you score 76% or higher, a Certificate of Completion will be

issued for you to print that will contain the continuing education

units earned for the online course.

To purchase this online training for just $195 with your credit card, go to www.welding.org and select online training.

4