Page 15 - HIWT Summer 2011 World of Welding

P. 15

hiwt@welding.org HOBART INSTITUTE OF WELDING TECHNOLOGY

COVER STORY

WELDING OPPORTUNITIES WITHIN THE WIND POWER

INDUSTRY

By Dale W Reckman

GLWN

As both the utility and community

grade wind market sectors continue

their unprecedented growth,

a multitude of manufacturing

opportunities abound for those so

qualified.

Wind power generation equipment

is generally classified in three

distinct market sectors being

residential, community and utility. Residential can be

classified as having a rated output of less than 100 kilowatt

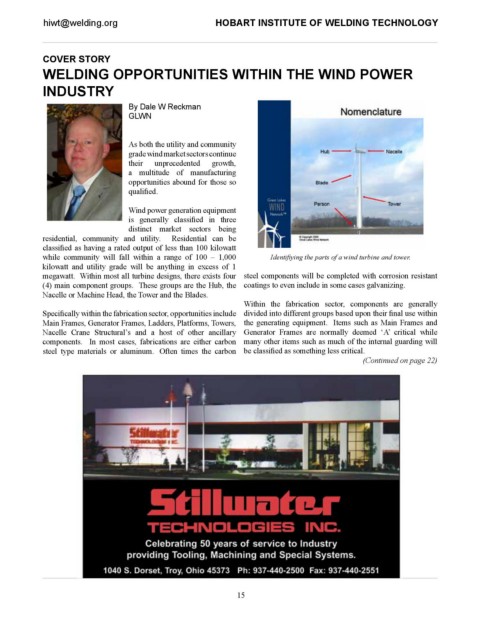

while community will fall within a range of 100 – 1,000 Identifiying the parts of a wind turbine and tower.

kilowatt and utility grade will be anything in excess of 1

megawatt. Within most all turbine designs, there exists four steel components will be completed with corrosion resistant

(4) main component groups. These groups are the Hub, the coatings to even include in some cases galvanizing.

Nacelle or Machine Head, the Tower and the Blades.

Within the fabrication sector, components are generally

Specifically within the fabrication sector, opportunities include divided into different groups based upon their final use within

Main Frames, Generator Frames, Ladders, Platforms, Towers, the generating equipment. Items such as Main Frames and

Nacelle Crane Structural’s and a host of other ancillary Generator Frames are normally deemed ‘A’ critical while

components. In most cases, fabrications are either carbon many other items such as much of the internal guarding will

steel type materials or aluminum. Often times the carbon be classified as something less critical.

(Continued on page 22)

15