Page 12 - HIWT Winter 2012 World of Welding

P. 12

THE WORLD OF WELDING http://www.welding.org

bug-o donates Modular driVe eQuipMent to

Hobart institute of Welding teCHnology

A new piece of automated

welding equipment that

will enhance training

demonstrations at Hobart

Institute of Welding

Technology was donated this

past summer by Bug-O®

Systems, Inc. of Canonsburg,

Pennsylvania. Jeff Nelson,

Welding Engineer at Bug-O

Systems coordinated the

donation.

The Modular Drive System

is a machine that allows the

operator to custom configure

one machine for various

applications and runs on

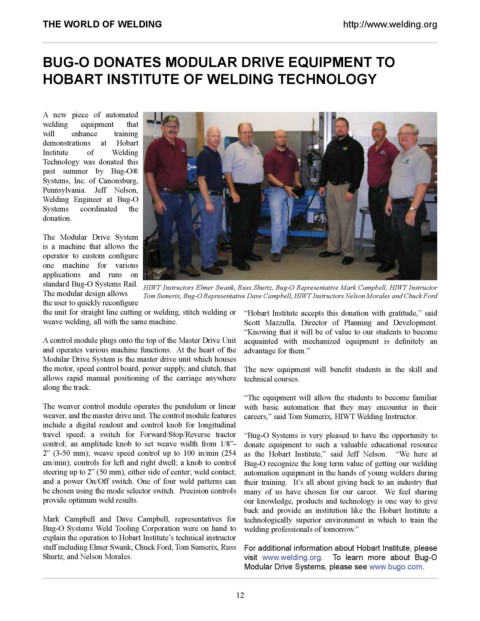

standard Bug-O Systems Rail. HIWT Instructors Elmer Swank, Russ Shurtz, Bug-O Representative Mark Campbell, HIWT Instructor

The modular design allows Tom Sumerix, Bug-O Representative Dave Campbell, HIWT Instructors Nelson Morales and Chuck Ford

the user to quickly reconfigure

the unit for straight line cutting or welding, stitch welding or “Hobart Institute accepts this donation with gratitude,” said

weave welding, all with the same machine. Scott Mazzulla, Director of Planning and Development.

“Knowing that it will be of value to our students to become

A control module plugs onto the top of the Master Drive Unit acquainted with mechanized equipment is definitely an

and operates various machine functions. At the heart of the advantage for them.”

Modular Drive System is the master drive unit which houses

the motor, speed control board, power supply, and clutch, that The new equipment will benefit students in the skill and

allows rapid manual positioning of the carriage anywhere technical courses.

along the track.

“The equipment will allow the students to become familiar

The weaver control module operates the pendulum or linear with basic automation that they may encounter in their

weaver, and the master drive unit. The control module features careers,” said Tom Sumerix, HIWT Welding Instructor.

include a digital readout and control knob for longitudinal

travel speed; a switch for Forward/Stop/Reverse tractor “Bug-O Systems is very pleased to have the opportunity to

control; an amplitude knob to set weave width from 1/8”- donate equipment to such a valuable educational resource

2” (3-50 mm); weave speed control up to 100 in/min (254 as the Hobart Institute,” said Jeff Nelson. “We here at

cm/min); controls for left and right dwell; a knob to control Bug-O recognize the long term value of getting our welding

steering up to 2” (50 mm), either side of center; weld contact; automation equipment in the hands of young welders during

and a power On/Off switch. One of four weld patterns can their training. It’s all about giving back to an industry that

be chosen using the mode selector switch. Precision controls many of us have chosen for our career. We feel sharing

provide optimum weld results. our knowledge, products and technology is one way to give

back and provide an institution like the Hobart Institute a

Mark Campbell and Dave Campbell, representatives for technologically superior environment in which to train the

Bug-O Systems Weld Tooling Corporation were on hand to welding professionals of tomorrow.”

explain the operation to Hobart Institute’s technical instructor

staff including Elmer Swank, Chuck Ford, Tom Sumerix, Russ For additional information about Hobart Institute, please

Shurtz, and Nelson Morales. visit www.welding.org. To learn more about Bug-O

Modular Drive Systems, please see www.bugo.com.

12